As we pulled into Touchstone Research Laboratory in the Triadelphia area of Ohio County, CEO and Founder, Brian Joseph, met us in the parking lot wearing a goofy pair of toy glasses – a gift from his five-year-old daughter. He walked us into the facility (while he made each of us try on those plastic coke-bottle glasses) and immediately stopped at a wall of Touchstone’s patents (they have approximately 60 at a recent count). As we moved on, noticing that there were also numerous plaques celebrating the sales of their inventions in nations all around the world, Brian commented on how hot the building felt that day.

“Our AC’s not working,” he mentioned, quickly turning to us with a wide smile and commenting, “Jeez, you’d think we’d be able to figure that out in here, wouldn’t you?”

He continued to lead us through the building, stopping proudly at a wall of diplomas. He quickly glossed over his honorary doctorate from West Liberty University (he is a proud Topper alum: biology and physics), and showed us his favorite piece of paper on that wall: his Romper Room completion certificate dated summer, 1967. The levity, joy and pride that he displayed at the beginning of our tour and interview characterized the rest of our time there. This is a man who loves what he does, loves the people he gets to do it with, and loves the community that his business serves.

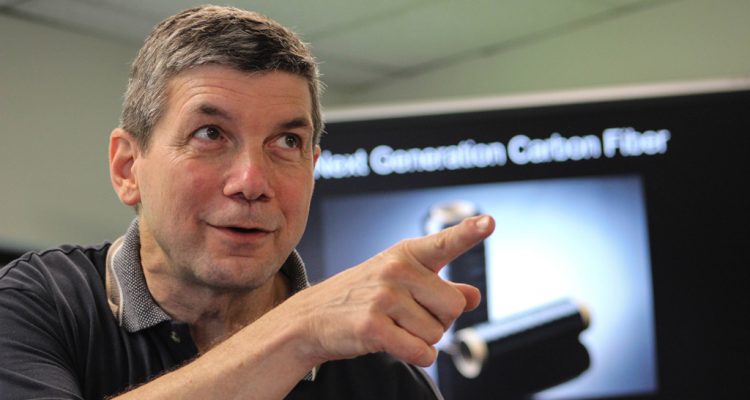

When we finally sat down to talk to Brian about the story and impact of Touchstone (in a conference room filled with – among other things – a line of carbon panels propped against the wall behind us, each of which had been struck by lightning to test their resilience), he decided that he’d start by sharing a presentation he uses when high school groups come to tour the facility. Too excited to sit down, he stood next to a large mounted flat screen display with a PowerPoint presentation that he was controlling from a laptop as he paced. His presentation starts with the premise that West Virginia has an identity problem. In this northern region of the state, we have a deep and accomplished history of entrepreneurship, cutting-edge technological inventions, and ground breaking manufacturing abilities. However, he tells us, as he tells his student groups, we have not taught our young people this history, and – therefore – they don’t believe that this place can ever again be an epicenter of greatness. Joseph disagrees.

A series of slides shows icons of local history, including a photo of Mark Twain as the spokesperson for Marsh Wheeling Stogies and the Fokker aircraft factory in Glendale. “I explain (to visiting students) that was then, now what’s going on today?” He shares the examples of more recent leading businesses including Kalkreuth Roofing, Gary West’s Valley National Gas company, and Ziegenflders popsicle factory. “Wheeling’s highly successful people aren’t very visible today. If they were all building huge houses and driving Porsches, kids would notice and they might not feel they need to move away to be successful. Our wealthy tend to show humility, but that’s not motivational to our aggressively upwardly mobile youth. ”

Precipitating Moments

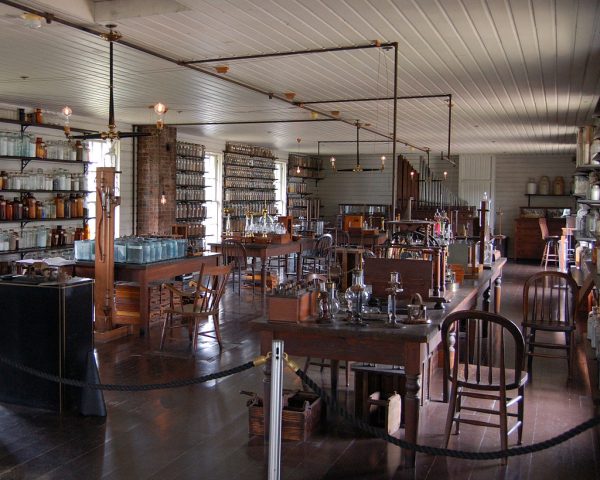

Brian describes visiting the Henry Ford museum and experiencing the Thomas Edison exhibit (in 1876, Edison built the first ever industrial research lab in New Jersey; it was later moved to the museum to be preserved).

“I tell this story to try to describe what we do here (at Touchstone). I never paid too much attention to Edison one way or another, but I went up there and walked through the place and thought, ‘This is completely familiar to me.’ Like a déjà vu kind of feeling. And I know what it is. In this facility Edison put out over 400 patents in 6 years. He invents everything from the microphone that lets a telephone work, the phonograph, the world’s first electric train, iron ore separation equipment… He does this with 22 people in the middle of nowhere, with most people not formally educated. Why did I feel the way I felt when I was in Edison’s lab? Well we both started research laboratories without ever having worked in a research laboratory before so I didn’t bring the modern research laboratory culture. We developed our own culture which happened to be incredibly similar to Edison’s.” While Edison put out a 400 patents in 6 years, Touchstone only puts out about one patent application per month.

Brian went on to discuss Edison’s method of management, describing him as an informal leader who was a co-learner and co-tinkerer alongside his “guys”, whom Edison called his “muckers”, because they all “mucked around” all day.

“He led his team but left room for initiative. He used humor constantly. One of his critics said, ‘He’s notoriously tolerant of incompetence’; I understand why he was seen that way! He’s not looking at one’s education or skill at a known task or how hard someone works but he’s looking for that person who sees the world differently. Sometimes that person doesn’t look overly competent.” Today, Brian gives talks at conferences on Edison’s management style.

While he connects his story today to the story of Edison and Wheeling’s rich past, he admittedly did not even know about these aspects of history when he started his own journey as a scientist, inventor and entrepreneur. Brian was inspired by a famous physicist of his youth, Dr. Robert Jastrow, who was a frequent guest on amateur-astronomer Johnny Carson’s show. His biggest influence was from a beloved cousin, Robert Lynch, who was a clinical chemistry professor at the Medical College of Virginia. Brian illustrated his scrappy and unconditional approach by describing how he started Touchstone Research Lab by rebuilding a second-hand electron microscope (which he bought for $100) in a rented basement room of the Carmelite monastery when he was 23 years old. He grew the business with a small loan from his mother used to buy an old downtown Wheeling building, with the high basement ceilings necessary to install a rebuilt IBM microprobe, purchased at a fraction of its original cost because of his ability to refurbish it himself.

Although Brian himself was not initially inspired by the rich history of this area, “I think that we could create excitement for kids to be motivated by (this history), and we have not done that. And I find that very frustrating.” Brian wants the young people in this area to use information available to them – data, records, their own observations – to develop the strong critical thinking needed to counter the information that they are bombarded with in today’s high-information era, and to challenge their own cognitive biases. “Science isn’t just a bunch of facts, it’s a way of thinking about things, interrogating the universe and finding out. It’s only through science and technology that the world gets better.”

“The rate of change here is unbelievable!”

Brian is a story teller. Ask him almost any question and he will at some point be able to fully answer it (he knows a little bit about absolutely everything), but you’re in for a wild ride along the way. His responses become adventures – full of fascinating and well-informed twists and tangents, the most exciting parts dramatically conveyed, and always with Brian’s consistent frenetic energy. By the time you get your answer, you realize you’ve received a lot more information than you’d originally bargained for. After hearing about the history of Wheeling entrepreneurs, the various scientists who inspired Brian, and even a little bit about the history of the Bible (not kidding), we were eager to hear the story of Touchstone today, and where Brian sees it going. He did not disappoint.

Using the props in the room that we were in, as well as quick drawings on his white board and the presentation that he used with the students, Brian told the story of an innovating, expanding and increasingly global company, connecting with the private and public sector to provide materials that no one else in the world can. In typical Brian fashion, he jumped around quite a bit as he described some of the products that he is most excited about, and our fascination with what was happening in this Wheeling facility grew with each new twist in the conversation.

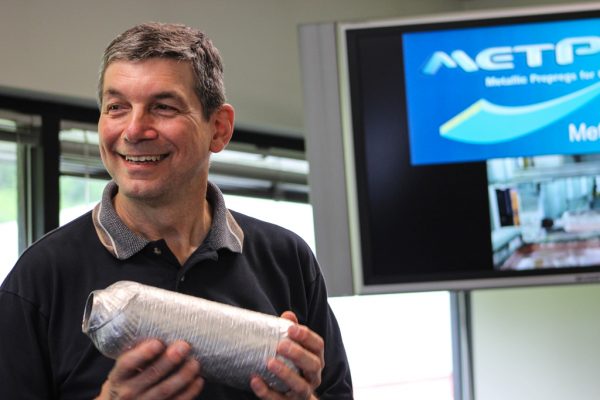

We learned about a new thermal protection system they are developing for a plane that travels over 3000 mph (you know, so it doesn’t melt in the sky!). Waving a sample tube in the air, he described an R&D program to create fiber reinforced aluminum rocket structures. The material is the weight of aluminum, the strength and stiffness of steel, and can withstand temperatures of up to 1000 degrees. This – the world’s strongest aluminum (yes, created here in Wheeling, folks) – will likely spin out to be a separate business, known as MetPreg. There’s even a fiber reinforced aluminum tape that is being used by NASA to stiffen the inside of launch vehicles and lighten up the weight of the actual rocket as it ascends into space. The tape will also be used to fix cracks in aluminum ships, and Brian predicts we will use this product in the future for things like cars and airplanes as well. “We are the only producer of this in the world … we have probably nine patents related to this.”

The story behind the multiple lightning-stuck samples was finally told. “As you remember, when NASA launches rockets, they always wait until the weather is good. That’s because if a rocket is hit by lightning, you can lose the entire rocket. Well, what if it’s a dark and stormy night, we want to be able to launch. So what if we make the surface of the missile something that’s good at taking the temperature, that’s electrically conductive enough to withstand lightning strikes?” He holds up one of the three foot by three foot pieces of material. “This is the composite space plane structure, hit by lightning, it has CFOAM carbon foam with other exotic materials on it.” He shows us a picture of the testing taking place, and then reflects on why he thinks innovations like this one were able to happen at Touchstone. “This is where the strength of this place is not in what you make people do, it’s in, I’ll say, doing a lot of listening, create the right environment. We had ideas to what we thought would work there, but a couple of the team members came up with a solution that was unbelievable. We have about 1.3 million dollars now to perfect that.”

Brian shared a dozen more examples of cutting-edge products being made, tested and sold out of Touchstone. Projects underway include molds and actual parts for next generation helicopters; molds for air travel vehicles that will fly both within and beyond Earth’s atmosphere; involvement in the creation of an airplane that can take off and land like a helicopter (i.e. no runway needed), and even an emerging partnership with a next-generation bicycle company. The most exciting tidbit that Brian shared was involvement with a certain company that just might become the leader in commercial space travel…

Using coal today: “Where’s the innovation?”

CFOAM carbon foam, Touchstone’s most well-known product, is made directly from coal. “I’m frustrated because in West Virginia we stomp our feet and say, ‘We want to burn it like we always have.’ Where’s the innovation in that? It’s embarrassing that that’s the only thing we can think to do. Aside from the whole argument of global climate change, which is real.” Yes, most of Brian’s most innovative inventions are made from coal. He believes that someday soon all rockets will be coated with a product that is made from coal likely mined in West Virginia. “So when you think coal, do you think of rockets going to space? No! But there’s more.” He then described a way that CFOAM will be used to absorb heat and store energy produced in solar thermal farms in American deserts that Touchstone is working on today. “So now you have solar energy being stored in coal. So you think they’ll like it in California? I don’t know! It’s sort of like mixed emotions for them! It’s coal… but it is solar, so…?”

Think about a large Navy ship’s exhaust system – huge, seven story tall towers. There are major corrosion problems with those exhaust stacks, which are currently made of exotic metals. Touchstone invented a solution that uses CFOAM with a ceramic liner so there is nothing to corrode. “So when we think about coal are we thinking about naval ships’ exhaust systems? No, but here we are. And this is going to be huge, this is going to go global and this is going to be in every large ship moving forward. I’ve got all the confidence in the world about that.”

Touchstone has used coal to create what Brian considers the most significant scientific instrument in the world right now. He held up an award from Northrop Grumman for Touchstone’s work on the James Webb space telescope – the replacement for the Hubble telescope. “I’ve been waiting for quite some time to be able to tell people about this. It’s eight times bigger, will be located a million miles from earth, but here’s what’s so exciting about this, it’s going to see back in time 13.4 billion years. Remember, the universe is only 13.7 billion years old. We will see the formation of some of the earliest galaxies. It’s unbelievable. To me, the Webb telescope will be the greatest piece of scientific equipment in the world, well maybe other than the Large Hadron Collider, and by the way they called us a couple of weeks ago…” Remember, we’re talking about things made from coal.

Leaving a Mark on Wheeling

As we were wrapping up our conversation, we asked Brian what he believed to be his company’s greatest impact on Wheeling. He named job creation as the obvious one. “We spent a lot of years incubating new technologies and we are in the process of spinning new companies out; we have spun out three already, and expect to spin three more out in next five years. Each will have its own growth path, so we should see a large number of high tech jobs.” There have also been two companies that have set up in the area, developed by former Touchstone employees. “That’s wonderful. We want to see Touchstone spawn other growth.”

“I end the presentation for each class of students like this.” He shows a slide of one person shaking hands with another, obviously in a professional setting. “I say, ‘I need two of you – just two of you – to graduate and start a business. If two people from every graduating class here started businesses, there would be jobs for the rest of you. And if no one does, most of you will leave the area. Remember, there is no greater good than to create a job for someone else.”

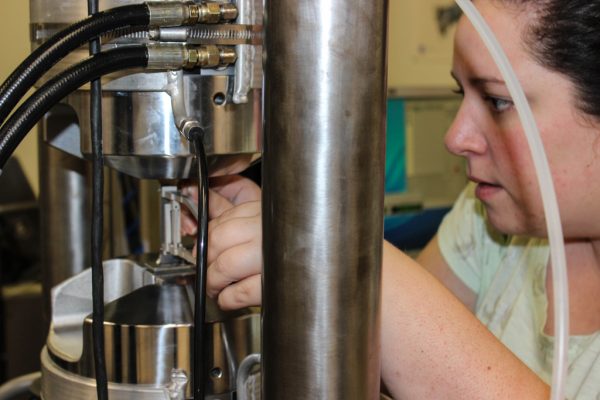

“One of the ways in which Touchstone is similar to Edison’s lab is the people. Edison hired people that could make anything. Many of them came off of farms. In the Weelunk area and at Touchstone, we have the most amazing collection of people. We are a culture of people who intuitively understand materials and know how to make things. This business wouldn’t work in most areas of the United States.

My thought is that the future here is bright for manufacturing – not like WWII manufacturing – but highly efficient and very advanced. A local company we should all be proud of is Eagle Manufacturing. They are very forward looking. We have the workforce here. We have an amazing workforce here.”

“I want kids to believe they can do this stuff. If they think the can, they will. If they don’t think they can, they won’t. Last thing I tell my young visitors is, ‘Don’t let anyone tell you that you can’t do these things. You absolutely can.’”

Photos by Jeremy Morris