She knew what Daddy did but seldom was offered a taste of what he did.

That’s because, if Lisa Allen, her older sister, Karen, younger sister Tobie, or younger brothers Pete, and Ed, wanted some Ziegenfelder’s ice cream or popsicles, they had to go to the store and buy it.

It was business, and it was a difficult one.

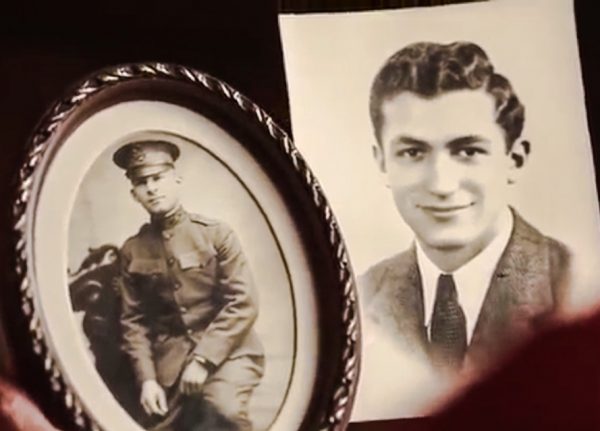

“We never had it at home. He never brought it home,” admitted Allen, now the president and chief executive officer of the Ziegenfelder Company purchased by her grandfather, Abe, and operated by her father, Charles Lando, for more than 60 years. “Another thing that I remember is that the customers were in this community, so he also taught us to toe the line and never step out of line. He wanted us to be respectful, to do the right thing, to be humble, and never to pull rank, and that was because they were customers of his.

“If he was going to be successful with the business, we had to be respectable kids, so that was a lesson we all learned. To be respectful,” she continued. “When I was a kid I remember we’d pull up in front in our family station wagon and you could smell the flavors. Not the ice cream, but the flavors,” she recalled. “I could smell the flavors of the popsicles more than anything. And it was a tough business back then because it was just a regional business and my father worked very, very hard to make it profitable.

“He used to have route trucks that would deliver up and down the river, and I also remember the layout of the facility. It was completely different than it is today. Most of the space that we are in today was all homes. And I also remember my father never being around when I was a kid. He worked all of the time.”

But today, the Budget Saver brand is a global product, and the company produces more than 2.5 million Twin Pops per day in its three facilities in Southern California, Denver, and in the East Wheeling section of the Friendly City. In fact, nearly 1.5 million popsicles are manufactured in Wheeling each day of every week, and though she consistently deflects credit the company has experienced, a tremendous amount of growth has occurred since Lisa began working with her father in 1999.

And she admits it wasn’t easy in the beginning.

“Earlier than when I actually started working here, I had gone to my father and asked him if I could have a job at a time when I was going through some changes in my life, but he said no,” Allen said. “He wanted me to go figure it out on my own because he always believed that if you make a decision, you needed to go figure it out.

“So that’s what I did for the next four or five years, but then all of a sudden my father was 75 years old, and I had to wonder what we going to happen to the business after he was no longer here. That when I spoke with him again, and I started here in August 1999,” she recounted. “He and I struggled for a while once I started working here, and that was because he was different. I was the high-risk taker, and he was 75 years old and didn’t want to take risks anymore. Eventually he gave us the rope to take some risks, and we started to grow.”

Allen is responsible for executive-level decisions, including talent development, growth initiatives, real estate and asset purchases, and capital expansions projects. She orchestrated the purchase of a factory in Chino, Calif., in 2011 and then bought a former Kroger’s facility in Denver in 2014. Allen also negotiated a purchase agreement with Walmart to place Budget Saver Twin Pops in all Superstores across the country.

“I have continued to take risks, but I do that while I am surrounded by people who understand their areas of expertise so we can all make collaborative decisions together so we can make sure it’s what is best for the business,” Allen said. “But it was my father who set the vision by making some very difficult decisions during his ownership. He was very innovative.”

Some may have believed he was losing his marbles, however, when in the mid-1980s he suddenly decided to sell off the ice cream portion of the Ziegenfelder’s business.

“That was a very interesting step when that decision was made, and I wasn’t here when that happened,” Allen recalled. “My father had brought all of the key employees together, and he told them that he was going to sell the ice cream business, and at that time ice cream was more than 50 percent of his business. And he sold it (to Borden’s).

“Those employees wondered what they were going to do during the winter months because no one ate popsicles in the winter. He told them that the business may go down, but he believed if they put everything they had into it, the business would take off again,” she continued. “And they believed in him, and the business did take off again because he focused not on where the revenue was but where the potential was.”

Twin Pop production was never more important but Charles Lando was determined.

“He believed it was the only thing he could do to stay in business at that time, so that’s what he did,” Allen said. “It was tough for him back then, it really was, and he was struggling. So his choice was to develop a product that would exceed everyone else’s. Not a high-end product, but just the best product.

“So he sourced the right flavors; he sourced the right sugar blend; and he decided to focus in on the consumer and not just the retail end of the business,” she continued. “So he took the value-price position, and the business started to grow. He made that call and that’s why I have always said that he pulled the slingshot back, and it was ours to execute.

“My father created the strategy, and he struggled early on with that strategy, but then it turned everything around for the company. What we have done since is realize that since it doesn’t cost a lot to make them, so we do not charge a lot to sell them. We do that by not changing the product much, and that’s why the Twin Pop is the same today as it was when he altered the focus of the company 30 years ago.”

One idea with which Charles disagreed involved moving the Ziegenfelder Company out of Wheeling and to The Highlands near Dallas Pike. In order to meet demand, a large production facility was needed, and the factory’s footprint in East Wheeling was squeezed by residential.

“After I had purchased 51 percent of the company, we started developing a plan to move the facility to The Highlands, and he was really upset with that idea. He was not happy about that, but at that time we felt it was going to be the best decision for us,” Allen said. “He used to try and change our minds, and he used to go up there and stare at the area that was in our plans.

“But what really happened with that plan was that by the time we had around 80 percent of the design work complete, we realized we were over our budget. That’s when minds changed,” she said. “And luck had a lot to do with it, too, because right at that time properties in this area came available and we were able to purchase them. So we expanded here instead.”

The Twin Pop, Allen explained, was invented during the Great Depression so that two children could split one for a nickel, and the Ziegenfelder Company Budget Saver began packing six assorted flavors in one bag in 1989.

Today the company offers not only the bagged and assorted Budget Saver Twin Pops in a plethora of flavors, but also Monster Pops, sugar free Twin Pops, Ice Pops and Fudge Pops. Cherry, orange, grape, banana, mango, lime, strawberry banana, pineapple passion fruit, Pina colada, citrus punch, tropical punch, mango punch, blue raspberry, cherry-pineapple, cherry-mango, and lemon-lime.

The “Box Variety” brand includes products like Dad’s Old Fashioned Root Beer, Tampico Ice Pops, Welsch’s Concord Grape Bars, Wyler’s Cool Raspberry Ice Pops, and Wyler’s Lemonade Ice Pops.

Cherry is the most popular twin-pop flavor, Allen said, and banana is second. The company received so many requests for an all-banana-flavored bag that they introduced the item in 1995.

But how many Wheeling-area residents even realize what products are manufactured here and how far the reach extends?

“I don’t think many realize that we produce more an than a million popsicles a day here, but that’s OK with me because what I hope people in our communities do realize is the environment that we have, the culture that we have, the leaders that we have, and that this is a great place to be,” Allen said. “And I believe we are getting better at what we do and how we go about it every day.

“It’s hard work here, and we understand that, and people have raised families by working here,” she said. “We laugh together, and we cry together, and we work very hard here. And everyone has a place. It’s a long table, and everybody’s role at that table is very important. We make sure we take care of everyone involved. That’s why we offer great benefits, a profit-sharing program, and a lot of different incentives.”

It is likely that on Oct. 28 many local residents learned a popsicle factory did exist in the Friendly City but only because of an ammonia leak that sent four employees to a local hospital for treatment before they were all released the same day.

“We didn’t produce very many popsicles that day here in Wheeling because we had to shut down. But that was OK because everyone was OK, and we had the facility evacuated in under 60 seconds,” Allen said. “It’s been fixed, of course, and as it was fixed in a way that would be safer for our employees in the future.

“I’m sure a lot of people who look at a business like this one may think we don’t care about the people who work for us, but that couldn’t be farther from the truth. That was not a good day because I was very, very worried about our people,” she continued. “We shut down everything involving that line until we were absolutely positive that it was repaired in a way that would supply a safer environment than it was before that line ruptured.”

Allen is often asked whether or not her father would be proud of how Ziegenfelder’s has evolved, especially since he initially turned away his daughter 16 years ago. Allen, after all, has guided the company to realize a 15-year compounding annualized revenue growth of 12 percent with consistent profitability each year. She also has overseen the acquisition and expansion of multiple projects in three states, over eight years, totaling more than $20 million and employing more than 300 team members.

“I hope so,” she said. “My father was tough, but he was also compassionate. There were two Charlie Landos, really. There was Charles Lando that everyone here knew, and there was Charlie Lando who his friends and his family knew.

“He was a kind, gentle, compassionate, loving person who was also a pretty hard boss to work for,” she admitted. “Those who really knew him, knew those things about him, and that’s why I think he would be proud of all of us. He may not be proudest of our growth, but I think he would be proud of the work that we have done in our communities.”

Her father passed away in 2005 but she is also confident he would beam about the fact Walmart and the Women’s Business Enterprise National Council have celebrated the Ziegenfelder Company as, “woman-owned.” Walmart, in fact, touts the fact with placards inside the coolers where Budget Savers can be found.

“He would be immensely proud of that if he were with us,” Allen said. “We’ve been women-owned since 2005, but it wasn’t until December 2013, when we decided that it was an initiative that we wanted to focus on. Once we did, it became a more significant piece of our branding.

“The attention can be a little much sometimes. It doesn’t embarrass me, but I don’t like the attention personally because this company is much more than just me. If it helps our company grow, if it helps other women in our business, and if it allows young women to say, ‘I want to be like that,’ then I will step out there and do whatever it is that I need to do.”

(Photos provided by the Ziegenfelder Company)