As the new Director of Assessment at West Virginia Northern Community College, my job is to work with faculty and staff from a wide range of disciplines to assess student learning in their programs. What knowledge and skills do we want students to take with them from an education at Northern? How do we know they are actually learning those things? How can we improve?

I’m broadly trained to help anyone in higher education with these questions, but, as a historian, some areas come easier than others. Standing in the welding lab during my first tour of Northern in November, I admit to feeling out of my depth. What is all this equipment for? What skills do welding students learn in their classes? What on earth is a bend test?

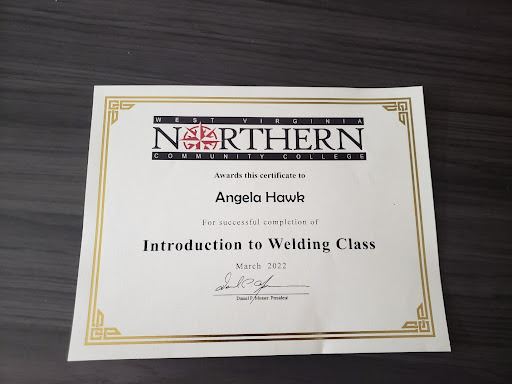

And that’s how I found myself one Saturday morning in a classroom learning all about 6010 and 7018 welding rods. WVNCC Welding Program Director Brandy Killeen was teaching her first Community Education “Introduction to Welding” course and for $50 I thought the time had come for me to learn the basics. After watching a short video, we went straight to it. Brandy walked us into the welding lab, handed us our protective gear, gave us a quick orientation, and let us loose on some scrap metal.

Of our small cohort, I was definitely the least experienced. I was the one asking simple questions like: “What is stick welding?” and “How is welding different from soldering?” (For the record, stick welding is when you use electricity to melt a metal filler rod and fuse it to another piece of metal. Soldering heats the metal just enough to bond it but welding actually melts the base metal.)

Patient and encouraging, Brandy showed us how to adjust the angle of the rod and create a short arc of electricity to begin the weld. Steadily she moved the arc in a line across the base metal, pulling a molten bubble along to the edge of the piece. Grabbing a wire brush and chipping hammer, she scrubbed off the slag (a chemical byproduct of the process) and revealed evenly spaced half-moons of hardened metal.

Doing my best to ignore the mild panic rising in my chest, I slotted a rod into the grip on the electrode holder and tapped it to my metal block. Instantly the rod fused to the metal and I had to start over. Gradually, I improved. Though my half-moons never looked as beautiful as Brandy’s, they compared favorably to some of the wonky welds in the practice pile. I was satisfied.

As I burned through rod after rod, I was struck by a few things: 1) how affordable this class was considering the school’s investment of time and materials; 2) that welding could feel downright meditative; and 3) that welding required a dexterity of hand that reminded me of one of my favorite pastimes – knitting. The latter seemed an odd connection to make until Brandy volunteered that she, too, is a knitter and considers herself a “fabricator by trade.”

Brandy still stands out in a male-dominated field but she doesn’t seem much phased by it. She took her first welding course with Lou Winters at Wheeling Park High School and was certified in 4G open root MIG welding when she was only 17.

She says her father, a roofer, was initially skeptical about this career path and wanted her to work with her head, not her hands. As Brandy points out, however, the two aren’t mutually exclusive. As Program Director and a Certified Welding Inspector, she welds, sure, but she also grants certifications, manages instruction, plans curriculum, assesses her courses, and promotes her program. The American Welding Society is recognizing her efforts, too: she’s been honored as a 2022 Future Leader and sits on the Board of Directors.

I’m not sure I’m ready to go out and buy my own stick welder, but I feel much more comfortable helping Brandy help her students now that I’ve attempted the skill. She says in the future she might offer two options — this “Introduction to Welding” course, which provides a broad overview of the field and its terminology, and a craft course where everyone will walk away with a finished product. She assures me a hand-crafted rose or even a fire pit is possible in the 4-hour time frame, so keep an eye out for the next course on the CourseStorm website or by following WVNCC on Facebook.