“Greeting,” the letter that brought him to boot camp began. “Having submitted yourself to a Local Board composed of your neighbors for the purpose of determining your availability for training and service in the armed forces of the Unites States, you are hereby notified that you have now been selected for training and service in the Army. You will, therefore report to the Local Board named above at Chapline Street, Wheeling, W.Va. at 6:30 a.m. on the 24th Day of April, 1941.”

George had broken the news gently to his fiancé, Mabel, and his future in-laws, Tom and Lizzie Minns, the blind proprietors of a small confectionary across from the Centre Market. George and Mabel postponed their wedding. George brought his barber tools home from the shop where he worked on Wheeling Island to Tom and Lizzie’s apartment for safekeeping. He walked alone to the Federal Building before sunrise on April 24, 1941 with a little bag of personal items to begin what everyone thought would be one-year of service in the U.S. Army.

George was assigned to the 201st Infantry, a force composed of mostly West Virginians and a great many Wheeling natives. George naturally gravitated to the Wheeling boys when they were herded into a vast empty gymnasium and ordered to change from their civilian clothes into their first set of fatigues. A fellow Wheeling native that George had seen around town occasionally proudly ambled up to him.

“Griffith. Right?” asked the newly minted soldier. “I thought I recognized you. Do your fatigues have brand on the inside anywhere?”

George looked.

“Nope, sure dont. Why?”

“Look at mine,” George’s new friend said holding his pants out for George to see. “Look at that boot. Know what it means?”

“I do,” George answered. “I’ll be darned. It’s just like CCC camp all over again. Same thing happened there.”

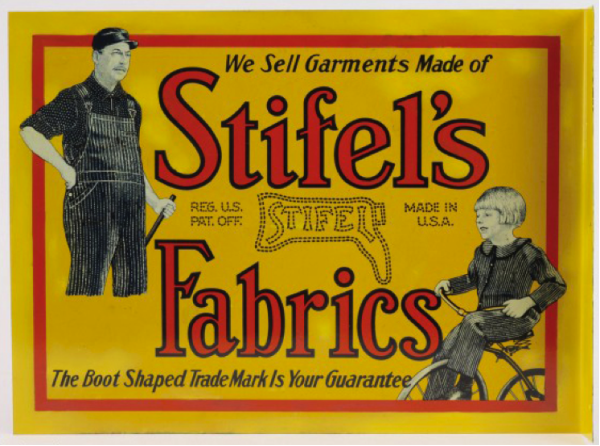

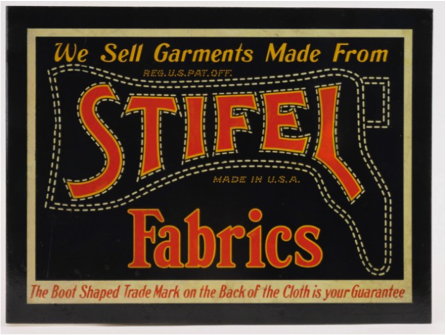

The object of the soldiers’ conversation was a small brand that featured a horizontal boot with the name “Stifel” clearly evident inside the cartoon-like image. The word Stifel means ‘boot” in German. The brand meant the Army fatigues were made of a blended material that was colored and treated in Wheeling and sold in bulk to another contractor that made the uniforms for the military. The brand didn’t appear on every item of clothing the Army had made for its troops out of the tons of cloth that came from Wheeling, but it did appear at least once on each bolt of cloth shipped from Wheeling. Sometimes, the piece of material with the brand made its way into the finished product.

The object of the soldiers’ conversation was a small brand that featured a horizontal boot with the name “Stifel” clearly evident inside the cartoon-like image. The word Stifel means ‘boot” in German. The brand meant the Army fatigues were made of a blended material that was colored and treated in Wheeling and sold in bulk to another contractor that made the uniforms for the military. The brand didn’t appear on every item of clothing the Army had made for its troops out of the tons of cloth that came from Wheeling, but it did appear at least once on each bolt of cloth shipped from Wheeling. Sometimes, the piece of material with the brand made its way into the finished product.

George knew a little about Stifel. He had tried to get a job there once in the mid 1930s before he joined the CCC. But, his new pal was a fountain of knowledge about the company because he actually worked there before Uncle Sam came calling, He launched into a history lecture about his employer that drew the attention of all the Wheeling boys in the 201st who were supposed to be changing into their new Army clothes.

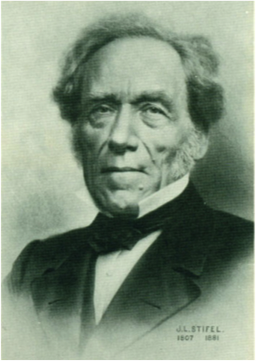

“Quite a coincidence that we might be getting ready to fight Germans in these outfits,” the wiry little Stifel worker from Wheeling said. “Old man Stifel, the guy who started the company in Wheeling, was from Murtenburg, Germany. His name was Johann Ludwig Stifel. How’s that for a mouthful? In the company, we just called him J.L. or the old man.

“He came to Wheeling alone with no money in 1834. They say he worked on a farm at first, but, since he was a dyer by trade, he decided to take a chance and start a little business. It was a little cleaning and dying shop in a log cabin up on North Main Street.”

Several more Wheeling boys gathered around the ex-Stifel employee to hear more about the start of the company that by 1941 operated in a big plant between Third and Fourth Streets on Main Street in North Wheeling.

Several more Wheeling boys gathered around the ex-Stifel employee to hear more about the start of the company that by 1941 operated in a big plant between Third and Fourth Streets on Main Street in North Wheeling.

“The story I got from some real old folks who still work at the plant is that old man Stifel bought some bolts of unbleached cotton from a local dry goods store and set about dying it himself and then selling it to folks who made shirts and dresses out of it. The proceeds he used to buy more bolts of cloth. That’s how the J.L. Stifel Company started out.”

The solider told about how in making the dyed and printed cotton material that made the company famous, workers would boil up to 50 yard bolts of fabric in soda to take out all the traces of starch and other additives and hung it out to dry. That made the fabric ready for printing. Then, they used one-inch thick blocks of wood made out of pear, maple or gum trees. Stifel himself drew designs like flowers, circles or leaves on the wood blocks and then used a sharp knife to make a depth in the block deep enough to guarantee a clear impression when pressed against the cloth. They saturated the block with a chemical that resists coloring and stamped the fabric, which was laid flat and pinned down. After that block printing process, the cloth was dipped into big vats of indigo blue and then washed. The stuff they used in the stamping blocks to resist color is what made the pattern in the cloth.

The solider told about how in making the dyed and printed cotton material that made the company famous, workers would boil up to 50 yard bolts of fabric in soda to take out all the traces of starch and other additives and hung it out to dry. That made the fabric ready for printing. Then, they used one-inch thick blocks of wood made out of pear, maple or gum trees. Stifel himself drew designs like flowers, circles or leaves on the wood blocks and then used a sharp knife to make a depth in the block deep enough to guarantee a clear impression when pressed against the cloth. They saturated the block with a chemical that resists coloring and stamped the fabric, which was laid flat and pinned down. After that block printing process, the cloth was dipped into big vats of indigo blue and then washed. The stuff they used in the stamping blocks to resist color is what made the pattern in the cloth.

“They called the product ‘calico,’” the Stifel storyteller continued as an Army drill sergeant poked his head in the gymnasium door to check the progress of his new charges. “The process came to Europe from Calcutta, India where it was invented and that’s why they call it calico. ”

He said that by 1874 when old man Stifel retired, the plant was using steam printing presses to replace hand-operated printing and became the biggest calico printing outfit in the nation. It shipped material all over the world that was then made into clothing.

“Old J.L. Stifel made quite an imprint on Wheeling besides starting up one of our must successful industries,” the soldier said. “He helped operate the company that built and maintained the Wheeling Suspension Bridge. He was a big cheese at a couple of different banks and vice president of the old Benwood Iron Works. “Surprisingly, he was a big supporter of unions. He even played a key part in the Wheeling convention that separated West Virginia from Virginia and set us up as a whole new state during the Civil War. He was even one of the very first Ohio County Commissioners.”

The make-shift lecture about the Stifel company was interrupted when the agitated drill sergeant approached.

“Okay ladies,” he barked. “You have 5 minutes to get squared away and get into those fatigues before I introduce you to your luxurious new living quarters. Any man not ready will get a really up close and personal welcome to the outfit. Get it? Get Moving!

The men continued to change into the rugged dark-colored Army fatigues as the Stifel expert continued to talk. He explained that the generations of Stifels that followed in J.L.’s footsteps took the company to even greater heights and got involved with supplying material for the uniforms of armies all over the world.

“In the last war, they supplied colored fabric for the Belgian and French governments as well as the good old U.S. Army,” he said. “Then, after the war, they dyed and prepared all kinds of fabrics for use in work and sporting clothes. They cut way back on indigo blue calico about 1929 because the public’s taste kind of went another direction.”

He said that in the early 1930s, Stifel got permission to use a Sanforization process in preparing materials for new clothes, which is a way of stretching, shrinking and fixing the cloth in both length and width before cutting and producing, to reduce the shrinkage after washing. Then they branched out into working with mixing fibers of cotton and rayon.

“And presto, here we are in 1941 friends, wearing Uncle Sam’s best fashion statement courtesy of our hometown heroes the Stifels,” the solder said. “The Stifel family did alright. You know that big mansion out the Pike near Dimmydale? That’s the Stifel homestead these days (Now Oglebay Institute’s Stifel Fine Arts Center). It was built in 1910 by Edward W. Stifel. It has a swimming pool, putting greens, a tennis court, fancy ponds and some great gardens. My wife and I walked around it on the sidewalk one time. It’s enormous. It’s called ‘Edmar’ after Edward’s kids, Edward, Emily and Mary.”

“Time’s up you pinheads,” the sergeant bellowed, bringing an end to the impromptu history lesson. “Line up and stand at attention if you can manage it.”

If the ex-Stifel employee turned World War II solder/history lecturer were telling the story of Stifel in 2015, he would have a lot more to add—mostly good, but ultimately with a sad ending. No doubt, he would tell his colleague things like how:

- In 1942, the Stifel company earned the Army/Navy E Award for “high achievement in the production of war equipment.”

- In the early part of the 21st Century, a pair of work pants made out of Stifel material sold to a collector for more than $700.

- During its peak years, the plant produced 3.5 million yards of cloth per month.

- The company was unique among American fabric makers in that it often advertised its work in print ads and produced signage that hung in dry goods stores. Stifel didn’t make clothing but, perhaps because in its heyday there were so many people making clothes at home, it marketed directly so that people would know where the fabric originated.

- In a typical month in the late1940s, the plant consumed enough water to supply a town of 80,000 persons and its furnaces burned 15 railroad cars worth coal.

- The plant expanded in the 1940s into a 270,000 sq. ft. facility with a three-story power plant featuring 275-ft. smokestack which became a familiar Wheeling landmark.

- Edward E. Stifel, the grandson of Johann Ludwig, spearheaded a movement in the late 1930s and early 1940s to build the Wheeling-Ohio County Airport, which opened on November 1, 1946 and is officially known as Stifel Field.

- In 1957, a declining demand for cotton goods, development of synthetic fibers and foreign imports reduced the company’s ability to be competitive and, after 122 years, it was sold to a company called Indian Head. The last company president, W. Flaccus Stifel, announced that “the dyeing, printing and finishing of cotton goods just could not be done economically and competitively under current conditions.” Eventually, the printing presses capable of printing eight colors at one time were sold to textile companies in South America. The plant became idle. A fire in 1961 destroyed the buildings except for the iconic smokestack, but that came down with a wrecker’s ball in 1969.

But, Wheeling is still the beneficiary of five generations of Stifel Family civic engagement and support.

In 1976, Edemar was donated to Oglebay Institute and now serves as the Stifel Fine Arts Center with craft rooms, galleries and offices. Weddings and social events occur on its lawns and the room that once served as the family’s main gathering place now hosts jazz concerts and the occasional formal tea.

In 1976, Edemar was donated to Oglebay Institute and now serves as the Stifel Fine Arts Center with craft rooms, galleries and offices. Weddings and social events occur on its lawns and the room that once served as the family’s main gathering place now hosts jazz concerts and the occasional formal tea.

As for George Griffith and other Wheeling boys in the 201st Infantry, they were off to a brutal three-year deployment to Alaska’s Aleutian Islands where they were bombed and strafed by Japanese fighter planes, patrolled miles of frozen isolated coastline on the lookout for an anticipated Japanese invasion, and wiled away cold lonely hours by swapping more tales from home.