Before the current COVID-19 pandemic, students used the West Virginia Northern Community College (WVNCC) Makerspace as a collaborative workspace where they gathered together to learn and create while sharing ideas, knowledge and equipment.

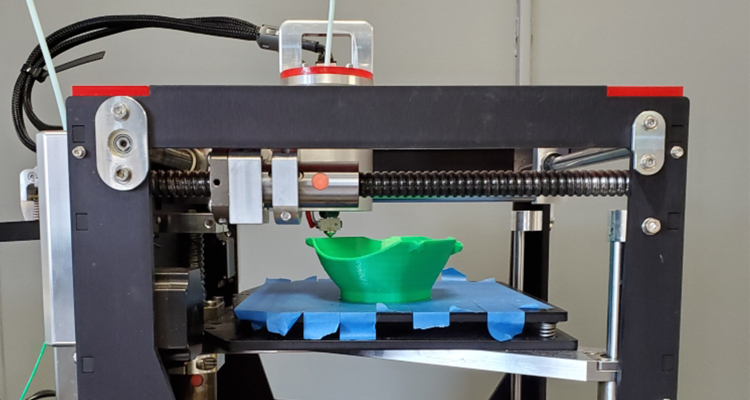

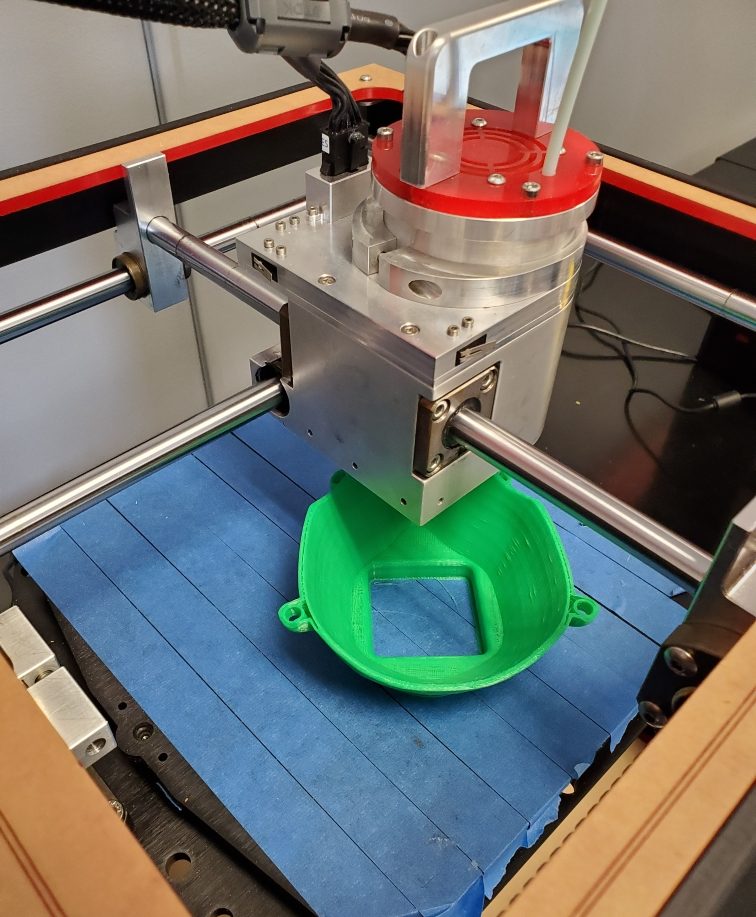

The space boasts a variety of creativity-enhancing equipment such as sewing machines, soldering irons, laptops and 3-D printers.

But when the shelter-in-place order became our new reality, the space could no longer be utilized in the way it had been.

David J. Stoffel, associate professor of computer information technology and division chair of science, technology, engineering and math (STEM) and business, and Julie Kloss, a WVNCC librarian who helps to oversee the Makerspace, chose to use the technology available to them to help produce personal protective equipment (PPE) for health care workers.

THE PRE-PANDEMIC MAKERSPACE

Stoffel is one of the original designers of Northern’s Makerspace. His desire was a place where innovation could happen. He did not have the coronavirus pandemic in mind at that time, of course, but Stoffel did envision a place where solid solutions for community problems could be created.

Kloss tells Weelunk, “Before this pandemic, the staff of the Learning Resource Center — consisting of myself, Tillie Ossman and Erica Shepherd under the direction of Director Patricia Stroud — were training students and staff how to use our machines in the Makerspace. We were having them 3-D print something small so they would get a feel for the machine. Our machines will 3-D print, laser cut and mill. The staff was in the process of learning the laser when the pandemic hit.”

As soon as the virus struck the local area, Stoffel found a good shield and mask pattern and began to print them. Getting a jumpstart on a problem is something he has always enjoyed.

“I have always run toward things when there is a need or a crisis,” he says. So when the National Guard put out the call for help, Stoffel was ahead of the curve and ready to respond.

THE WEST VIRGINIA NATIONAL GUARD’S REQUEST FOR ASSISTANCE

When the pandemic did hit, it immediately became clear that the need for masks and other PPE was seriously over-reaching the supply available to frontline medical personnel. PPE producers struggled to keep pace with demand, and the West Virginia National Guard (WVNG) was tasked with finding ways to assist with the rapidly growing shortage.

According to the WVNG website, “The novel coronavirus pandemic has nearly exhausted stockpiles of medical masks that serve as a first line of defense for medical professionals, long-term care workers and other first responders serving on the front lines of the COVID-19 fight. For this reason, the WVNG joined forces with our state’s academic institutions and businesses to collaborate in the development of a mask and filter that would alleviate the strain on the supply chain while seeking advancements in design, fit and decontamination.”

The WVNG reached out to WVNCC and other colleges through the West Virginia Higher Education Policy Commission and asked that any institutions with 3-D printers come up with a prototype for N95 masks.

WVNCC’S RESPONSE

When the WVNG’s request came in, Stoffel began working with colleagues throughout the state and with Col. Todd Fredricks, WVNG state surgeon, to ensure an approved prototype that would meet medical specifications.

“I was a little bit unsure in the beginning, but I have come to learn you either get scared or you lead,” Stoffel reveals.

And so the Makerspace pivoted to become producers of 3-D-printed N95 masks. Stoffel worked with a designer from Sheppard College to perfect the prototype’s design. With Kloss working onsite at the school, and Stoffel working remotely from home, the team buckled down and began printing masks 24/7 and has continued to do so for the past few weeks.

“I am glad to have Julie to handle the printing on campus — I couldn’t do this without her!” says Stoffel.

The first shipment has gone out to the WVNG for distribution, and Stoffel and Kloss vow to continue producing the masks around the clock for as long as it takes.

“We will keep producing these until they tell us not to. My hope is a large manufacturing company can take our prototype and mass-produce them soon,” shares Stoffel, who is currently working on a new mold that will enable the college to mass-produce the N95 masks more efficiently.

Kloss, too, is committed wholeheartedly to this work.

“The project is important to me as I have many friends and family that work in the medical field. The frontline people have worked tirelessly and deserve the best we can give. It’s my hope that these masks will help my family as well as the families of others to be safe.”

“Our employees did not hesitate to jump right in and utilize the technology we have at the college to assist in battling this pandemic,” adds WVNCC President Dr. Daniel Mosser. “These are unprecedented times, and they have shown extraordinary enthusiasm and innovation to do their part, and I couldn’t be more proud.”

Mosser is not the only one proud of the college’s contributions to the war against COVID-19.

On the WVNG website, West Virginia Governor Jim Justice says, “I’m unbelievably proud that even in these difficult times, we’re seeing yet another example of West Virginians doing what we do when there’s a problem — we step up, and work together to build a solution. And in this situation, developing protective equipment for the heroic men and women on the frontlines of fighting this terrible virus is a solution that could truly save lives. I’ve said for a long time now if we want to beat this virus, we have to band together and be ‘West Virginia strong’ in every way. That’s exactly what we’re doing. I thank everyone involved in this important effort from the bottom of my heart.”

Throughout his career, Stoffel has successfully combined problem-solving skills and technology to improve the world around him. He views this endeavor as an opportunity to give back to his community, set a good example for his children and help develop a new generation of innovators.

“Our often overlooked small community college is truly a gem of the Northern Panhandle,” Stoffel says.

It would seem that the school’s employees are also gems in their own right. These educators-turned-innovators have unmasked the satisfaction that comes from helping others.

“This project was brought to WVNCC, and we didn’t hesitate to help,” Kloss states. “While we want the Ohio Valley and beyond to know what we are capable of, we are not doing this for the accolades. We want to make a difference in any way we can.”

• A lifelong Wheeling resident, Ellen Brafford McCroskey is a proud graduate of Wheeling Park High School and the former Wheeling Jesuit College. By day, she works for an international law firm; by night, (and often on her lunch breaks and weekends) she enjoys moonlighting as a part-time writer. Please note that the views expressed in her writing are solely her own and do not necessarily reflect those of anyone else, including her full-time employer. Through her writing, Ellen aims to enlighten others on causes close to her heart, particularly addiction, recovery and equal rights. She and her husband Doug reside in Warwood with their clowder of rescued cats, each of whom is a direct consequence of his job as the Ohio County Dog Warden. Their family includes four adult children, their spouses and several grandkids.